By Tara Cielma

Welcome to “SAFER Scanning” – your resource for practical, evidence-based guidance on infection prevention in POCUS. Whether you’re a seasoned clinician or new to POCUS, this blog provides actionable advice, educational tools, and a framework for implementing safe, effective practices in your daily workflow.

S.A.F.E.R. stands for Secure, Assess, Follow, Eliminate, Reassess

Secure proper handling and storage of ultrasound probes and consumables (gel, wipes, sheaths/covers) to prevent contamination.

Assess the Spaulding Classification of the probe based on its next intended use (critical, semi-critical, non-critical) to determine the required disinfection level.

Follow the manufacturer’s Instructions for Use (IFU) and established infection control guidelines for cleaning, disinfection, and storage.

Eliminate pathogens by implementing evidence-based disinfection protocols and ensuring proper contact times for cleaning agents.

Reassess processes regularly through risk assessments, audits, training, and updates to protocols based on emerging research and guidelines.

The use of Point-of-Care Ultrasound (POCUS) is transforming modern healthcare, offering real-time, bedside diagnostic capabilities that empower clinicians and improve patient outcomes. However, with great potential comes great responsibility: as POCUS increasingly is utilized across disciplines, the critical need for robust infection prevention practices cannot be ignored. Improper probe handling and disinfection not only risk cross-contamination but also pose a significant threat of healthcare-associated infections (HAIs).

Despite its importance, infection control for POCUS is often hindered by a lack of standardized, practical guidelines tailored to its users. This gap leaves many clinicians uncertain about best practices, potentially compromising patient safety. This blog series aims to bring awareness. In this post, we will explore foundational principles of infection prevention, with a focus on probe disinfection, consumables management, and strategies to minimize HAI risk.

Why Infection Prevention Matters in POCUS

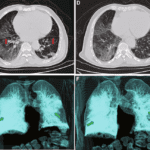

POCUS probes come into direct contact with patients and often harbor pathogens. Without proper disinfection, pathogens can inadvertently colonize and contaminate probes. Studies highlight this risk, showing that 45% of probes in Emergency Departments and Intensive Care Units have bacterial contamination, and over 50% have blood contamination.1 Additionally, up to 80% of probe handles remain contaminated when not disinfected properly.2,3

Effective infection prevention safeguards not just individual patients but also institutional reputations and regulatory compliance. These statistics underscore the importance of stringent infection prevention measures, ensuring that POCUS fulfills its promise of safe, patient-centered care.

Understanding the Basics: Spaulding Classification and Disinfection Levels

Central to infection prevention in medical device usage is the Spaulding Classification. The Spaulding classification is a widely accepted system that categorizes medical devices into three levels based on patient contact and the associated infection risk. It is the cornerstone of infection prevention, and the basis of guidelines and standards (FDA, CDC, TJC, AAMI ANSI, AORN, and more). It is a system that determines the necessary level of disinfection or sterilization based on device use. Here’s how it applies to POCUS:

Device Classifications and Disinfection Requirements:

- Critical devices: Penetrates sterile tissue or the vascular system. Sterilization required.

- Semi-Critical devices: Contact mucous membranes or non-intact skin. High-level disinfection (HLD) is required.

- Non-Critical devices: Contact intact skin only. Low- or intermediate-level disinfection is required.

Most POCUS probes fall into the semi-critical or non-critical categories. For example:

- Semi-critical probes: Used for endocavitary or transesophageal studies; requires HLD.

- Non-critical probes: Used on intact skin; requires LLD.

Adhering to these classifications ensures compliance with regulatory standards from agencies like the FDA and OSHA while protecting patients.

Disinfection Levels: High, Intermediate, and Low

Each disinfection level serves a specific purpose, targeting different pathogens:

- High-level disinfection (HLD): Eliminates all microorganisms except bacterial spores. Essential for semi-critical probes, typically achieved with FDA-regulated agents like hydrogen peroxide (VH₂O₂), high temperature water vapor (H₂O), oxidative chemicals like peracetic acid (PAA) and aldehydes like ortho-phthalaldehyde (OPA).

- Intermediate-level disinfection (ILD): EPA regulated. Effective against most bacteria, some viruses, and some fungi; suitable for some non-critical uses.

- Low-level disinfection (LLD): Effective against vegetative bacteria and enveloped viruses, often achieved with EPA-regulated wipes or sprays.

Pro Tip: Always follow the probe manufacturer’s Instructions for Use (IFUs). Contact (wet) time and proper application methods are critical for pathogen destruction.

Consumable Management: An Overlooked Infection Prevention Cornerstone

Infection control doesn’t end with probe disinfection. Mismanaged consumables, such as ultrasound gel and disinfectant wipes, can also introduce contamination risks. Here’s how to manage them effectively:

Gel is arguably the largest source of infection associated with ultrasound procedures.

Ultrasound Gel Best Practices:

- Single-Use First: Whenever possible, opt for single-use gel packets. Use for critical and semi critical procedures.

- Multi-Use Protocols: Use for non-critical procedures.

- Label bottles with an expiration date.

- Discard bottles after 28 days.

- Never refill or “top off” partially used containers.

- Store gel away from heat and direct sunlight to maintain its integrity.

Staying on Top of Expiration Dates:

- Regularly check the expiration dates of all consumables, including wipes and gels.

- Rotate and replenish supplies to ensure expired products are never used.

Following IFUs for Disinfectants:

Disinfectant wipes vary in formulation and effectiveness. To ensure proper use:

- Verify surface compatibility.

- Adhere strictly to required contact times to ensure pathogen elimination.

The Stakes: Cross-Contamination and HAI Risks

The consequences of lapses in infection prevention can be severe, exposing patients to life-threatening pathogens. For example, a meta-analysis revealed a 12.9% prevalence of bacterial contamination and 1% prevalence of viruses on semi-critical probes after low-level disinfection.4 Furthermore, failure rates for sheaths/covers/condoms used as probe covers reach 13%, and commercial covers fail up to 5%, emphasizing that covers alone are insufficient for infection control.5

In a related study, 74% of all immediate threats to life declared by The Joint Commission were linked to improper sterilization or HLD processes.6 These rates highlight the critical need for adherence to high-level disinfection (HLD) and standardized reprocessing protocols.

The good news? These risks are highly preventable. By adopting evidence-based disinfection protocols and rigorous consumable management, POCUS users can significantly mitigate these dangers, protecting patients while maintaining compliance with safety standards.

A Call to Action: Prioritize Infection Prevention

POCUS is a powerful tool, but its effectiveness must also align with safe practices. By implementing these principles, you can ensure that POCUS remains a safe, transformative force in patient care.

References:

- Keys, M., et al. Crit Care Resusc. 2015:17(1): 43-46

- Buescher DL, et al. Ultrasound Obstet Gynecol 2016;47(5): 646-651.

- Ngu, A., et al. (2015). Infect Control Hosp Epidemiol 36(5): 1-4.

- Leroy S, et al. J Hosp Infect 2013;83(2): 99-106

- Basseal JM, et al. Infection, Disease & Health. 2020; 25(2):77-81.

- TJC Quick Safety 33: Improperly sterilized or HLD equipment – a growing problem.